Multilayer PCB refer to the printed circuit boards which have more than three layer counts, it's normally pressing from copper foil and insulating material.

Multilayer PCB is actually using some double-sided PCB and putting insulating material prepreg between each layers, and then pressing them together to form a multilayer PCB, basically the layer count for multilayer PCB is even number.

In order to improve the reliability of metalized holes in PCB manufacturing, multilayer pcb manufacturer should use raw material with heat resistance and good stability on dimension, especially with small coefficient of thermal expansion in the thickness.

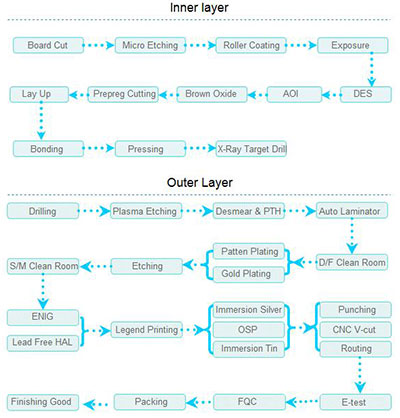

About the multilayer PCB manufacturing process, normally the PCB manufacturer should make inner core layer image first, and then press the inner core together with high temperature and pressure by pressing machine, the manufacturing process for outer layers is similar with double-sided PCB, below flow chart describe the detailed manufacturing process for multilayer PCB.