Flexible PCB or FPC is a patterned arrangement of printed circuitry and components that utilizes flexible based material with or without flexible coverlay. These flexible electronic assemblies may be fabricated using the same components used for rigid printed circuit boards, but allowing the board to conform to a desired shape (flex) during its application.

Rigid-flex PCB are the electronic boards using a combination of flexible and rigid PCB board technologies in an application, Most rigid flex PCB consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application. Rigid flex design doesn't just maximize space and weight but greatly improves reliability.

Flexible circuit and Rigid flex circuit are used extensively in applications and industries including:

| ● Communications | ● Industrial |

| ● Consumer Electronics | ● Aerospace |

| ● Automotive | ● Military |

| ● Medical | ● Transportation |

With a large number of investments on the facilities of flexible printed circuit board and continuously innovating the flexible circuit board manufacturing technology, Our Flex PCB Group is able to provide our customers with flexible PCB as well as Rigid-flex PCB with a great variety of technologies, from simple single-sided flex board to complex multilayer flexible PCB and Rigid-flex PCB. If you're looking for production of flexible printed circuit board or Rigid-flex PCB, our experts are there to assist you with every step of the process at the best value.

General specification for flexible & Rigid-flex printed circuit board

Layer count: 1-6L(Flex) & 2-10L(Rigid-flex)

Board thickness: 0.05-3.0mm

Base polyimide film thickness: 0.5 mil (12.5µ), 1 mil (25µ), 2 mils (50µ).

Copper thickness: 1/3oz (12µ), 1/2oz (18µ), 1oz (35µ), 2oz (70µ)

Stiffeners: Polyimide, FR4, Metal

Min trace width/spacing: 3/3mil(0.075/0.075mm)

Min drill size: 0.2mm

Surface treatment: Immersion Gold/Tin, Gold/Tin Plating, OSP

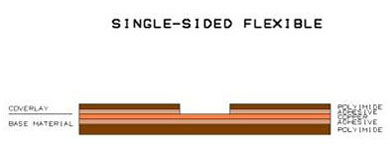

1. Single-sided flexible circuit board

Single-sided flexible circuits are the simplest and there for cheapest, consisting of a single conductor layer on a flexible dielectric film with the option of a coverlay or semi flexible liquid photo imagable solder resist (for some flex & stay applications). Parts of the flexible can be made more rigid by the use of additional stiffeners.

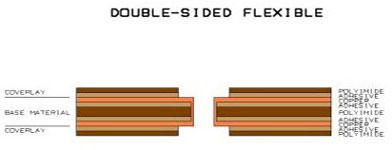

2. Double-sided flexible PCB

Double sided flexible pcb consist of two copper layers with a dielectric layer in between ,Normally connected with plated through holes, with the option of coverlay's or semi flexible liquid photo imagable solder resist (for some flex & stay applications). Parts of the flexible can be made more rigid by the use of additional stiffeners.

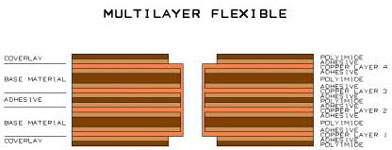

3. Multilayer flex PCB

Multilayer flex pcb consist of three or more copper layers with a dielectric layer in between, normally connected with plated through holes, with the option of coverlay's or semi flexible liquid photo imagable solder resist (for some flex & stay applications). Parts of the flexible can be made more rigid by the use of additional stiffeners.

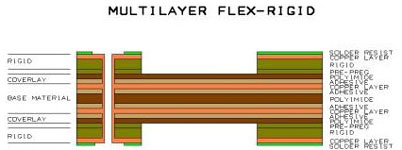

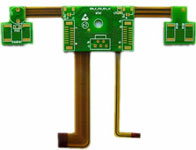

4. Rigid-flex PCB

Rigid-flex PCB consist of a mixture of flexible copper conductor layers on dielectric film & rigid copper material, normally connected with plated through holes. Coverlay's are applied to the flexible copper conductor layer & liquid photo imagable solder resist applied to the rigid areas.